Whenever a new technology comes along promising a “breakthrough” in an established industry, a certain level of healthy skepticism should be expected and even encouraged. If that breakthrough turns out to be proven by data with significant field performance improvements, as is the case with our Stirling engine freezers using less than half the energy of cascade-compressor freezers, this skepticism can be raised to the level of mythology by those who feel the need to defend the status quo.

This is a first of three blog posts that I will be sharing to address several myths being spread about the “compromises” of applying energy efficient technology to ultra-low freezers . . .

Myth Makers Spreading Fear about Energy Efficiency

Some in our industry have suggested that ULT energy efficiency comes at a price that is too great and risks the safety of precious biological samples. This myth was vividly represented to us in a recent email message we saw from a competitor who said, “Since the system is energy efficient, heat removal efficiency and capacity is sacrificed.”

To put it simply, this is not true. The amount of heat that must be removed from a freezer cabinet, at a given temperature, volume and insulation, is the same for everyone. It’s a fact that one unit of heat can be removed by a Stirling engine using less than half the energy of even the best cascade-compressor system. This fact is supported by a recently published report from the Better Buildings Alliance Laboratories, performed for the U.S Department of Energy – who has some authority in these matters. This independent study showed that the Stirling Ultracold freezer saved 66% in energy usage when compared to the average ultra-low freezer, as measured in power consumption per cubic foot.

Some have also suggested that a cooling system has to be anemic to conserve energy and this will sacrifice ULT pull-down and recovery. So let’s tackle that myth by looking at actual data, surveyed from what we believed to be the best competitive ULT freezer on the market . . .

The Pull-Down and Recovery Myth

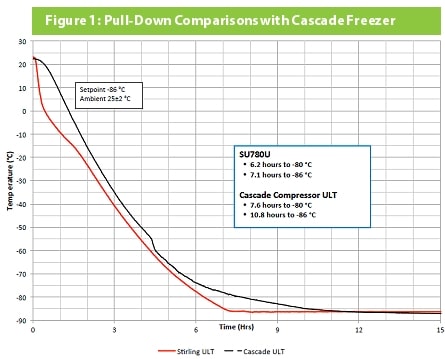

Again, it’s simply false to suggest that energy efficiency must come at the expense of temperature pull-down and recovery, as would occur with frequent freezer door openings. Figure 1 shows the pull-down of the Stirling freezer compared with an industry leading cascade system. Pull-down is from an ambient temperature of 25°C ± 2°C with the freezers empty. The Stirling freezer cools to -80°C 18% faster than the cascade system and 34% faster to -86°C. In the case of the cascade system, the cooling system is clearly at the limits of its capability and can only just reach the setpoint. In the case of the Stirling freezer it is clear that the control system intervenes to hold temperature at the setpoint. The Stirling cooling system has the clear capability to go to lower temperatures.

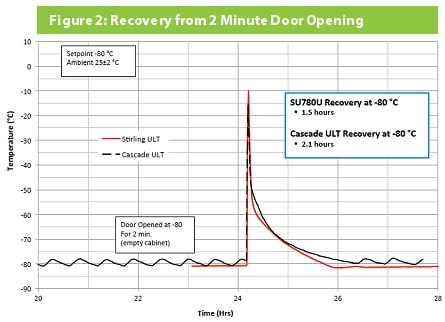

Figure 2 shows the recovery from door openings for the Stirling freezer compared with an industry leading cascade system. The inner and outer doors of both freezers are opened for two minutes in this comparison and the ambient is 25°C ± 2°C. Both freezers are empty – the most challenging condition for this test. The Stirling freezer recovers to the -80°C setpoint 29% faster than the cascade freezer.

There’s No Place for Myths with an Industry-Standard Test Method

Now that we have an industry-standard, ENERGY STAR® “final test method” from the EPA, ULT manufacturers can address these issues in a meaningful way, with objective data that provides real answers. It doesn’t serve our industry to put buyers in a position of deciding who to believe, when these questions can be answered by manufacturers presenting their EPA-compliant test data, as we have done.

I find it interesting that the myth makers represent ULT manufacturers who haven’t yet published their standardized test data to the EPA, as of the date of this posting.