We are now seeing the emergence of a new generation of biological and clinical research where critical samples and assets often have higher levels of temperature-sensitivity and variability, with the essential need for reliable thermal protection to maintain long-term efficacy. The uncertainty factor created by these emergent materials is that no two are alike and many of them require different storage conditions dependent on the research ambient environment and the level of cold required to slow or completely pause biological processing. This gives rise to a new bioprocessing discussion about ultra-low temperature (ULT) freezer flexibility and reliability in the biological materials research and development conversation, with the continued importance of maximizing assets and streamlining storage processes.

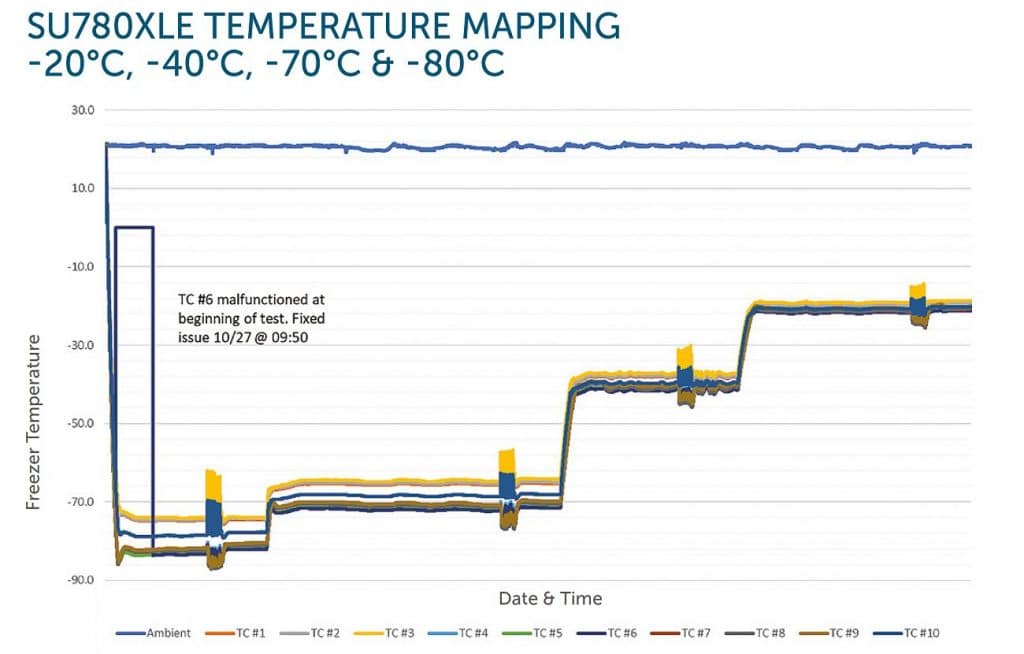

For this reason, Stirling Ultracold has recently published a new white paper documenting “SU780XLE Temperature Testing,” which summarizes reliability and uniformity test results from our upright ULT freezer at a wide variety of temperature setpoints. This is of particular relevance considering the need to safely store the emerging variety of advanced biogenic materials and the challenge of maintaining controlled performance at a wider ultracold temperature range (-20°C to -80°C) using prevalent compressor-based technologies in today’s ULT market.

The Test and Methods

Following the industry-standard ENERGY STAR® Program Requirements for Laboratory Grade Refrigerators and Freezers, Version 1.1, Section 5 Test Setup, this white paper shares results of tests that were conducted at five different setpoint temperatures: -20°C, -40°C, -50°C, -70°C and -80°C. At all setpoints, the SU780XLE achieved a steady state condition after 8 hours for testing cabinet temperature stability and uniformity, followed by successive door openings for temperature recovery tests that followed procedures outlined in Section 6.2C, Version 1.1 of the ENERGY STAR test protocol.

Higher Performance Over a Wider Temperature Range

As documented in this new white paper, Stirling’s SU780XLE upright ULT freezer showed improved uniformity and door recovery times at warmer setpoints. After door opening events at the warmer temperature setpoints, the upper cabinet warms by 3 degrees, or less, and the cabinet recovers from a door opening event within 20 minutes, or less.* At steady state, a +/-1°C temperature tolerance is maintained, regardless of temperature setpoint or location within the cabinet. Commercially available, compressor-based freezers do not have this setpoint flexibility without compromising temperature uniformity and other key ULT performance factors, much less measuring the actual time it takes to return to setpoint rather than simply marketing the time it takes to get within range.

Why It Matters

This kind of ULT performance data is increasingly important as we now see major pharma companies validating their ultra-low freezers at -50°C for storage of many types of biologics. Not only is it easier to maintain tight temperature uniformity for improving GMP compliance, but this also saves energy and reduces operating carbon footprint at the warmer setpoints.

The ability to modulate the Stirling engine’s cooling power allows Stirling Ultracold freezers to be the only commercial models capable of achieving a high level of performance over such a wide range of temperatures. As the ULT landscape and drug requirements continue to evolve, Stirling models will be the most economic selection because they are flexible and can be trusted to meet the widest range of ultracold temperature setpoints at high efficiency, without sacrificing key performance parameters.

Download our new white paper: SU780XLE Temperature Testing

* Following the test protocol specified by ENERGY STAR, door recovery time was measured back to temperature setpoint; not just within acceptable setpoint range.