When working toward environmentally sustainable cold storage solutions, selecting energy-efficient ultra-low temperature (ULT) storage equipment is an important starting point. The advent of lab freezer energy standards and test protocols, particularly ENERGY STAR® certification introduced in 2017, gave the industry a new tool to guide energy-conscious freezer buyers towards reduced plug loads and associated carbon footprint.

With expansion of ULT freezer energy certification, many buyers now have a generalized misperception that similar energy/sustainability benefits apply to the entire field of “certified” freezers, when in fact there is a widening range of energy performance among qualifying models. This is just one reason why sustainable biostorage should not end with shopping “windshield stickers” and requires a more holistic approach.

Consider Freezer Heat Rejection Effects on HVAC

Freezer energy ratings do not account for the impact ULTs have on interior spaces where humans work—they dissipate a lot of heat to keep their samples cold. Essentially, ultra-low freezers are heaters affecting the external laboratory environment, and the people nearby who depend on HVAC systems to maintain a comfortable work environment. According to the American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE) guidelines, we can calculate the HVAC effects of this heat output per unit as follows:

(Freezer kWh/day energy use/0.024) x 3.4 = Heat Dissipation load to HVAC in BTU/h

Although it varies by seasonality and climate, roughly 29% additional energy from heat rejection is consequential, scaling up as more ULT freezers run 24/7/365 in a given space, and is even more substantial for legacy, ultra-low systems that use significantly more energy.

In addition to its inherently efficient Stirling engine with remarkably low heat rejection, Stirling Ultracold’s SU780XLE upright ULT model offers another advantage for managing HVAC effects. Its unique optimized air flow design directs heat above work areas and toward room air return vents for maximum comfort, in contrast to other ULTs that mix rising heat into the room by venting at floor level.

Optimize Storage Temperatures by Sample Type

A proven method for lowering ultracold storage energy use is by operating at lower setpoint temperatures that are confirmed safe for different biological sample types. This can be accomplished without risking sample integrity and by better Understanding Temperature Ranges in Biological Storage. For example, -20°C to -40°C is a safe range for short or long-term storage of DNA and RNA, provided samples have been suspended in the right type of solutions prior to being stored.

Of course, this approach may present a practical challenge if all your ultra-low freezers use traditional technology, which can only deliver stable performance over a narrow range of temperatures. Now there are more flexible options available than assigning sample types to multiple freezer types, and more sustainable options to this dilemma than defaulting to the coldest ULT temperatures for all biological materials.

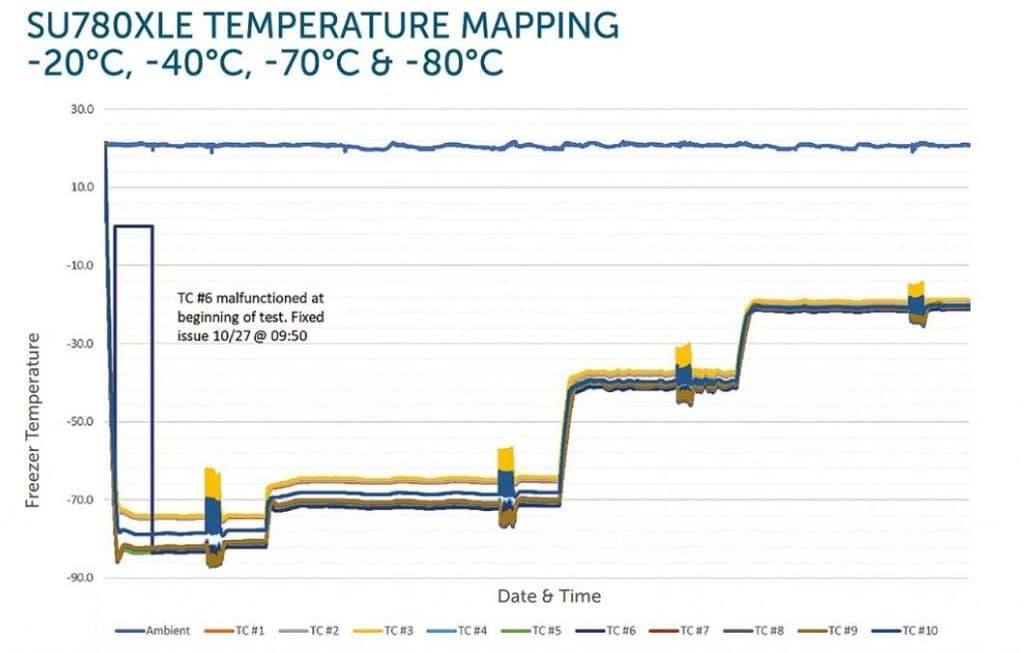

A more practical and energy-efficient solution is available by applying Stirling engine technology that delivers stable temperature performances over a wide setpoint range. With published Upright ULT Freezer Performance at Five Temperature Setpoints Ranging from -20°C to -80°C, the SU780XLE uniquely enables flexible matching of optimized storage temperatures in a single ULT freezer model.

Increase Storage Density Per Freezer

Another approach to more sustainable cold storage operation, which also conserves space, is to store more samples per freezer, thereby reducing total plug load and supporting infrastructure. This can be accomplished by organizing and consolidating your stored inventory through better sample management practices and racking. However, you should also consider storage capacity per freezer and footprint in ULT purchasing decisions, which varies by model.

With the highest storage density per footprint, the slim SU780XLE cabinet optionally holds up to 700 2-inch boxes. Not only does it reduce floor space requirements with its smaller base, narrower door swings and wall clearances, but its High-Density Rack System maximizes sample capacity per freezer in a high-efficiency ULT package, which also reduces the number of units needed for storing a given sample inventory. That’s fewer freezers to take up valuable floor space, use electricity, create heat and all the operating/infrastructure energy and carbon footprint that goes with it.

Consider the Source

True sustainability in any operation considers a range of environmental impacts from the products it uses, including effects from product manufacturing, energy, water use, packaging and end-of-life. For laboratory equipment and freezers, there is a third-party verification audit of Environmental Impact Factor (EIF), known as the Accountability, Consistency and Transparency (ACT) label from My Green Lab.

To complement its other sustainable advantages, The Stirling Ultracold SU780XLE has received the ACT label confirming its low EIF. Whether considering this ULT’s use of natural refrigerants with minimal Global Warming Potential or recyclable materials content, you can now be sure of its authenticity in meeting strict sustainability standards on multiple fronts.

Take a 360º Approach

It takes a well-rounded approach to implement sustainable cold storage solutions that address multiple environmental impacts over lifetime operation. This requires biostorage operations to apply a combination of resources, solutions and behavioral changes that go beyond freezer kWh/day ratings.

Contact your Stirling Ultracold/BioLife Solutions representative to learn more and calculate/compare lifetime sustainability factors for your next biostorage solution.