ULTRA

INSIGHTS

For further information contact

Stirling Ultracold today!

ADVANCING

SCIENCE

Advancing better, safer technologies for preserving your life’s work.

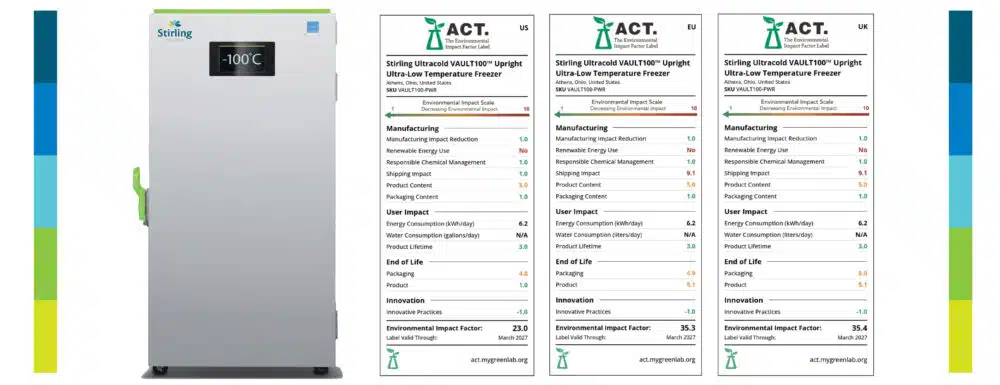

MINIMIZING

IMPACT

Minimizing environmental and climate impacts of research.

OPTIMIZING

OPERATIONS

Driving technology that reduces operating costs and increases research value.

©Copyright 2025 Stirling Ultracold

Design: The Unknown Creative