Our latest VAULT100™ Temperature Testing study demonstrates steady-state uniformity and stability. Conducted in a controlled environment using 15 calibrated thermocouples placed according to standard validation protocols, the VAULT100 maintained tight control and a 6°C top-to-bottom uniformity at a -80°C setpoint, supporting straightforward validation and full usable storage space.

The goal of this temperature study is to measure the steady-state uniformity inside the Stirling VAULT100 freezer at -80°C. The testing was conducted at Stirling’s Athens, Ohio factory, using fully calibrated measurement equipment in a controlled environment. Future tests will incorporate other temperature setpoints, door openings, and product freeze studies.

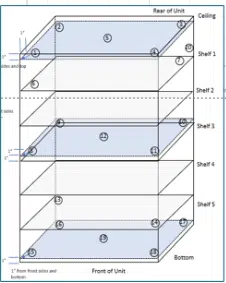

The VAULT100 setup consisted of the standard 5 evenly installed shelves (PWRS configuration). Thermocouples (bare) were installed 1” from the walls in 5 positions on 3 shelves (15 total probes).

This probe placement models standard validation protocols for most users. Figure 1. details the probe locations.

After probe installation, the freezer was powered on and brought down to -80°C. Once it stabilized (allowed 24 hours), steady-state uniformity was measured using a Yokogawa validator.

Figure 1.

TEST RESULTS

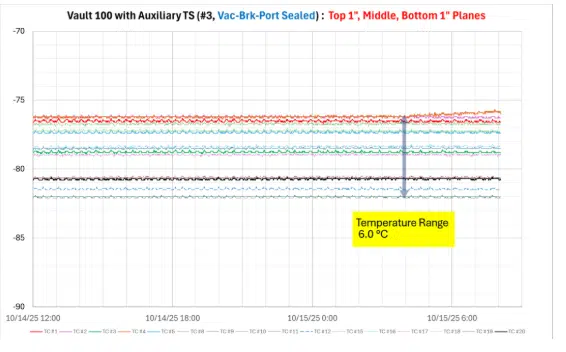

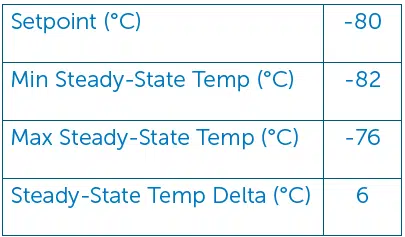

Overall test results are detailed in Figure 2 below. The freezer maintained a 6°C spread from setpoint top

to bottom. The overall results are summarized in Table 1.

Figure 2. Table 1.

CONCLUSION

The Stirling engine contained in the VAULT100 modulates cooling power much like cruise control in a car – by simply adjusting amplitude when over or under a desired temperature. This allows it to have very tight stability at all temperatures. The uniformity top to bottom of the freezer is 6 degrees Celsius, allowing straightforward validation and full use of the freezer.

About Stirling Ultracold and Global Cooling: Global Cooling, Inc. manufactures and sells Stirling Ultracold freezers, a new generation of environmentally friendly ultra-low storage solutions which operate between -20°C and -86°C. These freezers do not use compressor-based or cascade refrigeration systems. They use patented free-piston Stirling engine technology that was originally developed for energy, aerospace and industrial applications before successful commercial application in ultra-low temperature cooling systems.

How about testing with loads (boxes/trays) and comparing with empty?

That’s not a bad idea! I will pass this recommendation on. Thank you!